Fast Shipping

Paccar MX SCR | A041C815, 1934705PE, A041C814, 1893740PE, 041C815, 041C814

Quality Parts

Best Pricing

- Description

- Shipping & Delivery

OEM Replacement for Part #: A041C815, 1934705PE, A041C814, 1893740PE, 041C815, 041C814

Currently not for sale or installation in California.

Specifications

|

Brand |

Dinex |

|

Engine Manufacturer |

Cummins, Paccar |

|

OEM Part Number |

A041C815, 1934705PE, A041C814, 1893740PE, 041C815, 041C814 |

|

Aftermarket Part Number(s) |

58090, OTR58090, C0167-SC |

|

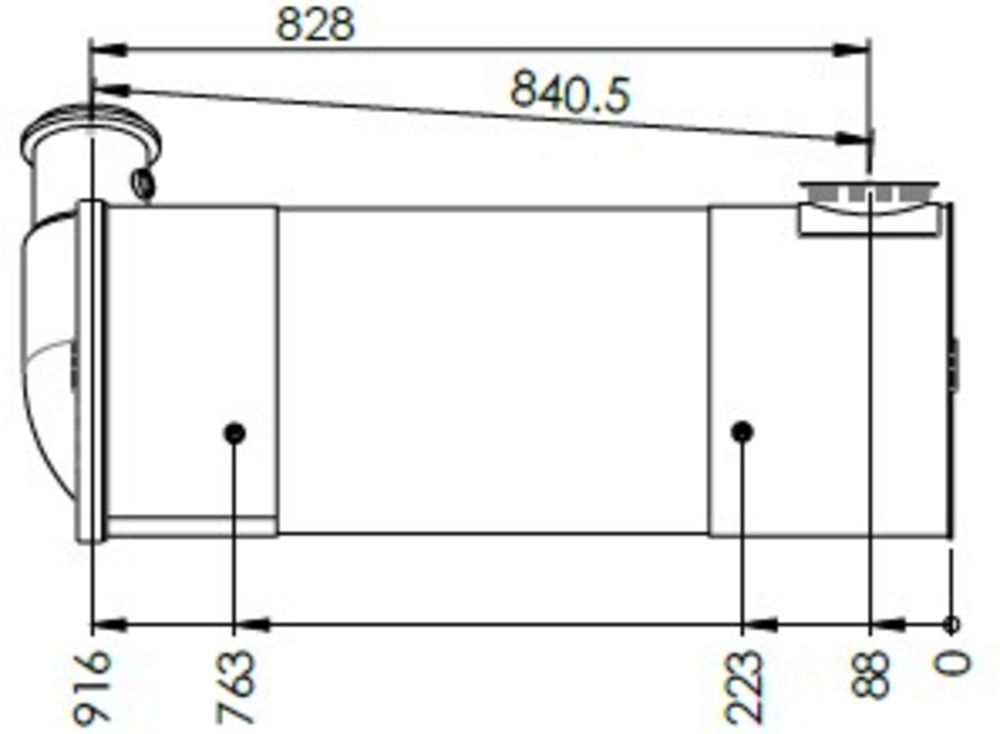

Product Dimensions |

36.06 x 13.62 x 13.62 in |

|

Weight

|

124.14 lb |

|

Warranty

|

3 year unlimited mileage

|

Selective Catalytic Reduction (SCR)

The primary function of SCR catalyst in a diesel after-treatment systems (ATS) is to convert harmful nitrogen oxides (NOx =NO + NO2) in the exhaust gas to nitrogen and water. The SCR reaction takes place on the catalyst, in the presence of NH3 generated from AdBlue (Urea and water solution) upfront the SCR catalyst.

EPA advanced emissions regulations need above 95% NOx conversion levels and all Dinex SCR technologies achieve conversion levels well above this limit.

Dinex has a wide variety of SCR catalyst technologies which can be selected based on actual applications and ATS temperature levels. Typically, titanium-vanadium based technologies are suitable for applications, where the exhaust gas temperature is not exceeding 550 degrees C level. Cu-Zeolite and Fe-Zeolite technologies are suitable for conditions where the exhaust temperatures exceed well above 600 degrees C.

The most widely used SCR technology in advanced regulations is Cu-Zeolite based. The Dinex technology is typically characterized by high NOx conversion activity in wide temperature window, low NO2 formation, and very low NH3 oxidation, even at high temperature (optimal Urea utilization).

Dinex meets all levels of regulation

The Advanced US EPA07/10 regulations need complex after-treatment systems (ATS) to fulfill all regulatory requirements. After initial implementation in year 2007, US EPA regulations have been updated step by step over the years with primary focus on real driving emissions (RDE) and in-service conformity.

Dinex supports Heavy Duty and Medium Duty commercial vehicles with advanced catalyst coating technologies (DOC, DPF, SCR), which are among the best in class. The wide range of technologies provide the flexibility to modulate the ATS layout to the full benefit of our customers as per their duty cycle and application requirements. The catalyst technologies have been rigorously tested by major OEMs world-wide and meet the most stringent engineering targets and real driving emissions performance requirements.

With close to 30 years of experience in canning & housing as well as patented technologies for compact mixers, Dinex builds robust and flexible ATS canning to meet a variety of packaging and space requirements.

We offer many different shipping options from our brands,

please review the maps below for more information.

Shipping, Delivery & Pickup

This Shipping & Delivery Policy is part of our Terms and Conditions (“Terms”) and should be therefore read alongside our main Terms: Terms & Conditions - DPF Sales

Please carefully review our Shipping & Delivery Policy when purchasing our products. This policy will apply to any order you place with us.

What are my Shipping, Delivery & Pickup Options?

In-Store Pickup

Our CA warehouse offers in-store pickup for all in-stock clamps and gaskets only. Pickups are available Monday-Friday 8 am – 5:00 pm. An email confirmation will be sent to you when your order is ready for pick-up. Please wait for that email confirmation before going to the location for pickup.

Carriers

FleetServ dba DPFSales uses various carriers to ship your order based on individual or combined item(s), quantities, sizes, and weights.

Free Shipping

We offer free Economy and Standard Ground Shipping for specific regions on qualifying DPFs, & DOCs. Excludes SCRs, One-Box and units above 80 lbs. For all our Clamps and Gaskets we offer free Standard Shipping as well as expedited shipping options for an additional fee.

Order Processing and Handling Time

We strive to process online orders as soon as possible, typically 1 business day. Orders placed after 3pm PST are not processed until the following business day. Orders are processed Monday - Friday, except on nationally observed holidays. Orders placed on weekends or holidays will be processed on the next available business day. You will receive an email notification when your order has shipped. Your shipments tracking number will also be provided. Please allow up to 24 hours for your shipping information to be available. Additional delivery days may apply in some instances, such as hazardous items, oversized items, truck freight items, select zip codes, and remote delivery areas.

Shipping Charges

Shipping charges are calculated based on delivery method, weight and dimensions of each item and the shipping destination. Shipping charges are displayed at checkout and are adjusted as changes are applied to your cart.

International Shipping

We do not offer international shipping.

Exceptions and Regulations

Shipping is only available within the continental United States. We do not ship to Alaska, Hawaii, or U.S. Territories. We presently do not ship to PO boxes or to APO/FPO addresses.

What happens if my order is delayed?

FleetServ dba DPFSales is not responsible, nor in control of transit delays once an item has shipped. The buyer is responsible for providing an address that carriers recognize as a deliverable address. Unfortunately, we have no control over a shipment once a package departs the facility. If there are any issues with delivery for reasons out of our control (address provided is not accurate, issues within the shipping company, etc.) we are not responsible for shipping delays. We are not responsible for errors made by the shipping carrier, such as delayed items or lost packages. We are not responsible for delays in shipping due to acts of God that are out of our control, such as epic snowstorms, natural disasters, or any other extraordinary circumstance that causes unforeseen interference with carrier routes. Please see our terms and conditions for more information.

Should you experience any issues with delivery, or do not receive your order within a reasonable time of the expected delivery date, please contact us.

Questions about returns?

If you have questions about returns, please review our Return Policy here: Return Policy - DPF Sales

How can you contact us?

If you have any further questions or comments, you may contact us by:

- Phone: (888) 315-4228

- Email: info@dpfsales.com

Each sale of Products shall be shipped in accordance with the IncoTerms 2000 specified in the RWAI Quotation or RWAI Order Confirmation. If shipping instructions are not so specified for any supply of Products, such supply shall be shipped ex works (IncoTerms 2000). Ex works deliveries of the Products are deemed complete upon release of the Products to the Customer’s carrier at the applicable manufacturing facilities located in Concord, Ontario, Canada as specified by RWAI in the RWAI Quotation, the RWAI Order Confirmation, or otherwise. If the Customer is unable or unwilling to accept physical delivery at the time specified, RWAI may store or arrange for storage of Products at Customer’s cost and the delivery of such Products shall be deemed complete as of the first day of storage.

Unless otherwise expressly provided by RWAI in a RWAI Quotation or RWAI Order Confirmation, or otherwise implicit in the IncoTerms 2000 specified for a particular supply, the price of the Products shall not include sales, use, excise, value added or any similar taxes, duties and other export/import charges, any inspection or testing fees or any other tax, fee, penalty or charge of any nature whatsoever imposed currently or in the future by any federal, state or other government authority, upon or with respect to the sale, purchase, delivery, storage, processing or use of any Product or upon payment to RWAI, and all such taxes, fees and other charges shall be paid by Customer in addition to the price of the Products. In the event RWAI is required to pay any such taxes, fees or other charge, Customer shall reimburse RWAI therefor.

Time for delivery of Products is approximate and starts to run on the latest of the date specified or confirmed in the RWAI Order Confirmation, or the receipt by RWAI of any advance payment, credit approval or any security for the balance of the purchase price, as applicable, each as may be requested by RWAI. Unless otherwise specified or confirmed in a RWAI Order Confirmation, RWAI shall not be liable for losses of any kind incurred by the Customer for delays in or failure to deliver all or any part of the Products. Changes in the delivery schedules requested by the Customer must be in writing and received by RWAI at least two (2) business days prior to the previously scheduled shipping date. RWAI is under no obligation to accept any changes in delivery dates requested by the Customer.